Three Capes Track Lodges

Architectural cladding made from COLORBOND® steel proved to be the ideal material for these two environmentally sensitive walking track lodges, in the wilderness south-east of Hobart.

Words: Editorial team led by Alice Blackwood.

Photography: Brett Boardman

Project Summary

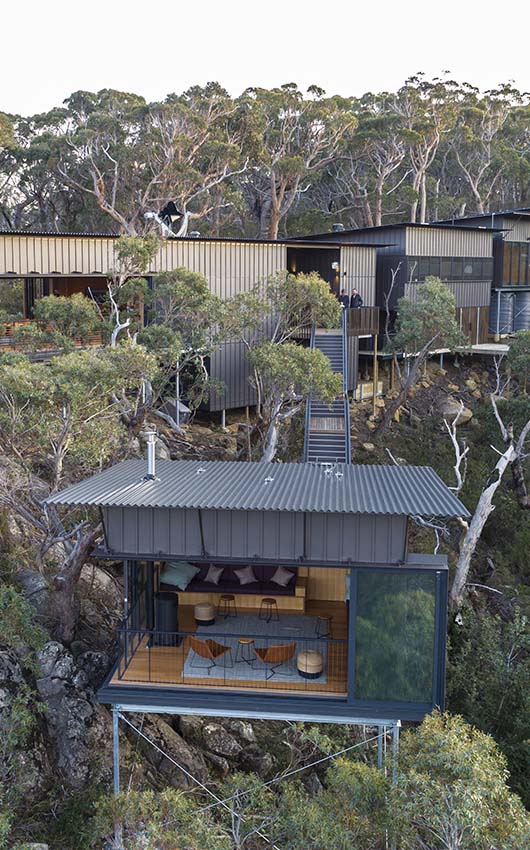

In the Tasman National Park, Andrew Burns Architecture has designed two walking track lodges, where the use of steel allowed for environmentally sensitive structures that blend into the landscape.

Blending In

Tasmania’s spectacular wilderness areas are renowned for their rugged beauty and pristine habitat. Inspired by the environment, many intrepid travellers have visited to explore the terrain by foot, so the tradition of accommodation-based guided walks in Tasmania is well-established.

The first walk – at Cradle Mountain – was launched in 1987 by architect Ken Latona and town planner Joan Masterman. They pioneered the early growth of comfortable camping and environmentally friendly tourism at multiple sites across Tasmania.

Latona and Masterman sold their Tasmanian Walking Company (TWC) to Brett Godfrey and Rob Sherrard, both of whom are committed to maintaining its legacy.

In 2016, the Tasmanian Walking Company (TWC) appointed architect Andrew Burns to oversee the design and development of two new facilities along the existing Three Capes Track: Crescent Lodge (to the west of the Tasman Peninsula) and Pillar Lodge (to the east).

Latona famously remarked: “I really think that people go to these places to see the places. They don’t go there to see fancy buildings. The architecture can be quite humble.”

This ethos informed Burns’ approach to the Three Capes project. “The client all-along said that the hero in this project was the landscape, and the architecture should heighten the experience of the landscape, not dominate it,” he explains.

Both Crescent Lodge and Cape Pillar Lodge follow a linear typology, which references Latona’s Bay of Fires Lodge (2000), to prioritise the spectacular views.

This is partly evident in the linear planning, which Burns describes as “a logical typology for a lodge building”, because it leads the eye towards the view. It can also be seen in various details throughout the new buildings, such as the profiled roof sheeting made from COLORBOND® steel; the eaves detailing that relies on exposed outriggers to eliminate the need for rafters in the eaves; and the combination of lightweight steel and timber-framed structures, which help to minimise the impact on the environment.

Burns spent much time getting to the sites, marking them out to ensure the buildings sit well within the topography, and take full advantage of extraordinary views towards Cape Raoul and Cape Hauy.

His design was also informed by constraints from the remote location and limited access, because everything – from building materials to construction equipment to workers – had to be flown in by helicopter. Hence, steel’s light weight as a construction material and its ease-of-prefabrication made it ideal for the project.

The buildings were designed to allow maximum flexibility in construction. The two sites utilise the same structural systems, and steel was integral to the project due to its great strength, slenderness and spanning capacity.

“There were some very long span openings, up to 10 metres,” Burns says. “The intention of this was to open the building dramatically to the landscape. The long spans were achieved with steel.”

In reviewing the design of both lodges – and drawing on Latona’s model – Burns observes that there is almost the sense of an over-scaled house with all the domestic intimacy that implies.

The kitchen/living/dining space is the central gathering point, a low-key area where guides and guests can mingle. A secondary lounge area peels off from the main space, accessible via an outdoor walkway.

The entire project was prefabricated by builder Adam Ritson of AJR Construct in Devonport, which produced components of various sizes that ranged from individual steel beams and columns to trusses (for the sub-floor structure and communal areas) to prefabricated steel modules (for the sleeping quarters).

These components were transported by road to a nearby landing-stage seven minutes’ flight away, and then flown in by helicopter and carefully positioned into place from the air.

Galvanised steel was the material of choice for the subfloor framing components (structural steel in the form of Rectangular Hollow Sections [RHS)], Square Hollow Sections [SHS] and I-beams) to achieve absolute stability for the buildings, and to accommodate 23 underfloor* custom-made AQUAPLATE® steel rainwater tanks.

AQUAPLATE® steel was developed specifically for the storage of drinking water; it is produced with a base of galvanised steel that is laminated with a food-grade polymer film on the inside.

Because the water tanks are visible below the structures, the outer surface was pre-painted in the COLORBOND® steel colour Monument® to complement the lodges’ colour palette.

Across both sites, the distinctive roof elements – featuring generous eaves and a dark-toned COLORBOND® colours palette – blend in well with the bush environment.

"We used COLORBOND® steel in the LYSAGHT CUSTOM ORB ACCENT® 35 profile in the colour Monument®," says Burns. This profile is known for its striking visual appeal, achieved through corrugations 120 percent deeper and 50 percent wider than a conventional corrugated profile.

"It's quite a chunky profile with its thicker gauge and a longer spanning capacity, which enabled a very minimal roof structure with limited steel purlins," he says.

Importantly, the overhang in the roof* meant that both the upper and underside would be visible, so the material was a custom order, because it was painted in the colour Monument® on both sides.

"That was a special run," notes the builder Adam Ritson. "Because the roof is an honest thing, you can see the underside of the steel everywhere where it overhangs."

The dark Monument® COLORBOND® colour of the roofing plays a key role in the overall palette. Burns points out that the architects followed a general principle of layering from dark tones externally to lighter tones internally. Contrasting with the darkness of the steel, the warmth of timber was employed on the exterior facade.

Further refinement is also apparent in the way the steel-framed balustrading subtly links the timber walkways and decking. Their soft, recessive dark tone connects the buildings to the bush surrounding them.

"We wanted the buildings to display a clear lineage to [Ken Latona's Bay of Fires Lodge], so we reinterpreted the characteristic steel detailing in that project, particularly the eave outriggers and metal roof sheeting," says Burns.

Fundamental to the whole strategy – and going back to Ken Latona's philosophy – was to "touch this earth lightly", as architect Glenn Murcutt famously said.

The slim roofing architectural roofing made from COLORBOND® steel seems to cantilever almost like a feather beyond the edge of the building, thanks to the slender steel outriggers that support the eaves, which allowed the main members in the walls to be kept very slim.

"This was in keeping with our architectural intent of creating a sense of lightness in the landscape," says Burns.

Notes:

*Warranty subject to application and eligibility criteria. For full terms and conditions and to determine the eligibility of your project for warranty visit the BlueScope Warranty website or call BlueScope on 1800 064 384

“The client all along said that the hero in this project was the landscape, and the architecture should heighten the experience of the landscape, not dominate it.”

Andrew Burns Andrew Burns Architecture

Project information

Architect

Andrew Burns Architecture

Project

Three Capes Track Lodges, Tasmania

Awards

- 2020 Australian Institute of Architects National Architecture Awards, Commercial Architecture – Commendation

- 2020 Australian Institute of Architects Tasmania Chapter Awards, The Colin Philp Award for Commercial Architecture

Location

Three Capes Track, Tasman Peninsula, Tasmania View on Google Maps

Copyright © 2020 BlueScope Steel Limited ABN 16 000 011 058. All rights reserved.

No part of this publication may be copied, reproduced or distributed without consent. BlueScope Steel Limited, to the extent permissible at law, is not liable to any person for loss or damage arising from reliance upon information contained in this publication. The articles featured in this edition of STEEL PROFILE® are sourced, written, fact-checked and curated by the authors with editorial contribution from BlueScope Steel Limited. Any statements or opinions attributed to a person are the views of that person alone and do not necessarily reflect those of BlueScope Steel. The decision to use any particular product or material in the projects featured in this publication was made by the team involved in each project and not BlueScope Steel Limited. While care has been taken to verify the accuracy of details in this publication, BlueScope Steel Limited assumes no responsibility or liability for any errors or omissions in the content of this publication. All information is provided with no guarantee of completeness or accuracy.

Images shown throughout have been reproduced to represent actual product colours as accurately as possible. However, we recommend checking your chosen colour against an actual sample of the product before purchasing, as varying screens and devices may affect colour tones and finishes.

Every project is different and not all products are suitable for all applications, projects and environments. You should confirm the suitability of particular products for your project by contacting the supplier directly and by obtaining information and advice specific to your circumstances.

BlueScope generally recommends the use of COLORBOND® steel or ZINCALUME® steel for the majority of external cladding applications. BlueScope recommends routine preventative maintenance for eaves and other “unwashed areas” of structures that may not be regularly cleaned by rainfall. For information about product maintenance, including preventative maintenance, please call BlueScope on 1800 753 658. To determine whether a BlueScope warranty may be available for use of a product in your particular project, please visit bluescopesteel.com.au/warranties.

COLORBOND®, ZINCALUME®, LYSAGHT®, CUSTOM ORB ACCENT®, AQUAPLATE® and ® colour names are registered trademarks and ™ colour names are trademarks of BlueScope Steel Limited.

Submit your project

We encourage you to share your projects for consideration in a future issue of STEEL PROFILE® magazine. We invite you to submit projects that feature a ground-breaking or an innovative use of steel. We love celebrating and writing about such projects!