Australian National Maritime Museum

The strong yet light steel construction of naval vessels has been mirrored in the unique architectural facade of the new Waterfront Pavilion which celebrates them.

Words: Micky Pinkerton.

Photography: Paul Bradshaw

Project Summary

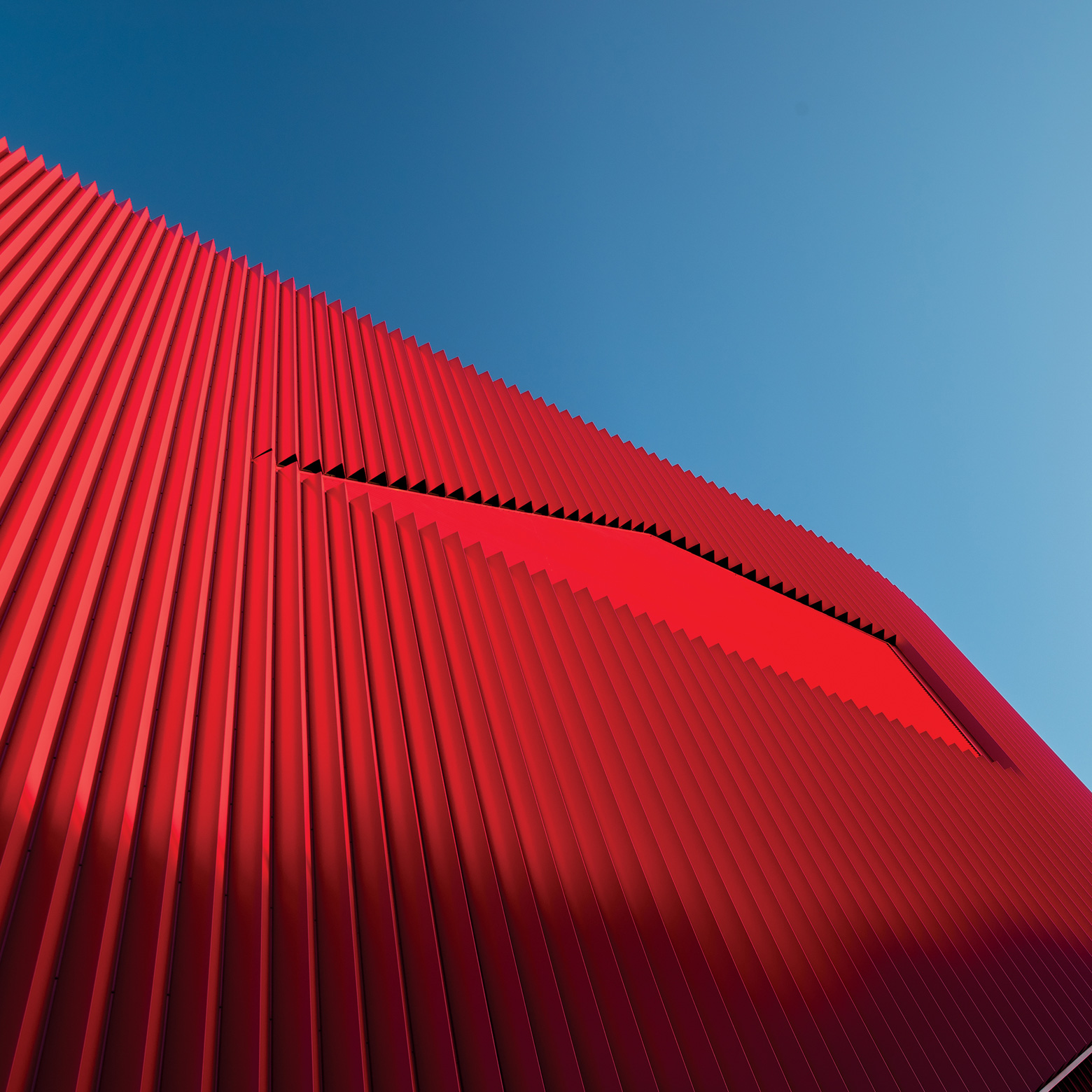

FJMT’s design for a Sydney waterfront pavilion building echoes the shapes and strong-yet-light construction methods of naval vessels, with a twisting carapace of rhythmically offset composite steel panels.

Ship Shape

Controls are good because you have to work with them,” declares James Perry from the deck of HMAS Vampire, a 118-metre Destroyer at anchor in Sydney Harbour. He could be a naval captain extolling the character-building benefits of the tightly confined maritime life on board the ship, or its submarine counterpart, Onslow, moored nearby.

Instead, Perry – an architect at Francis Jones Morehen Thorp (FJMT) – is referring to a slither of steel that sits between the two vessels, a twisting pavilion complete with a control panel that is the latest building in a series that collectively make up the Australian National Maritime Museum (ANNM) in Darling Harbour. It’s been some time since Vampire and Onslow saw active service, but their essential characteristics continue to impose constraints on those who work with them. Perhaps only an architect could see those limitations in such a positive light.

And controls there were-aplenty on this project. A skinny pier with minimal access in one of Sydney’s busiest precincts. Zero scope to put services beneath the building. An iconic parent building just to the west – a Bicentennial Philip Cox no less. A tight budget. Multiple stakeholders. Some might argue that this is standard fare for architects, living as they do in the extreme problem-solving world that is design. The ANMM Waterfront Pavilion, however, takes those challenges to new levels, fitting tightly as it does between two large, hard objects that are constantly moving, side to side with the currents and wind, and up and down with the tide.

Vampire and Onslow – decommissioned in 1986 and 1999 respectively – have been in situ at Darling Harbour for more than a decade. They form a key part of Sydney’s Maritime Museum experience in that they provide visitors with access to the defence ship and submarine environments, taking the conceptual premise of museum exhibits to a tangible, real-world level. Serviced for many years by a temporary ticket booth and nothing more, the museum guardians engaged FJMT via a selected tendering process to deliver a permanent access facility. The brief sought a building that moderated the physical space between the vessels externally, and that enhanced the onboard experience with appropriate interactive displays internally.

“The museum board was visionary about what they wanted and was very supportive,” says Perry. “This building needed to have its own identity but at the same time not overwhelm either the submarine or the warship.”

“The fifth elevation was paramount because of the significant corporate buildings looking back on the building. We needed a roof profile that was incredibly neat”

James Perry Architect - Francis Jones Morehen Thorp (FJMT)

Preliminary discussions led to a design premise that ensured the building could occupy its place and respect the main maritime building, but more than anything it had to respond to the vessels. It’s ironic, then, that two such clinically engineered and man-made entities are the controls to such an organic shape, a stretched pipe rhythmically punctuated by vertically ridged segments. The form distorts at its middle, physically submitting in shape to the conning tower of the submarine and the bridge of the destroyer. This deferential nod to the sea craft produces a dynamic and elegant structure from every angle and distance.

“We started with a tube and then looked at the way you could articulate that tube, which brought a few things into play,” says Perry. “It was about building material selection, it was about scale, it was about having some height and understanding the profile of these two vessels. They’re not flat – they have scale and they have variation. The building is almost pinched at the top, and that was as a result of that form development. The fifth elevation was also paramount because all those significant corporate buildings on the city fringe look back on this building. We needed a roof profile that was incredibly neat.”

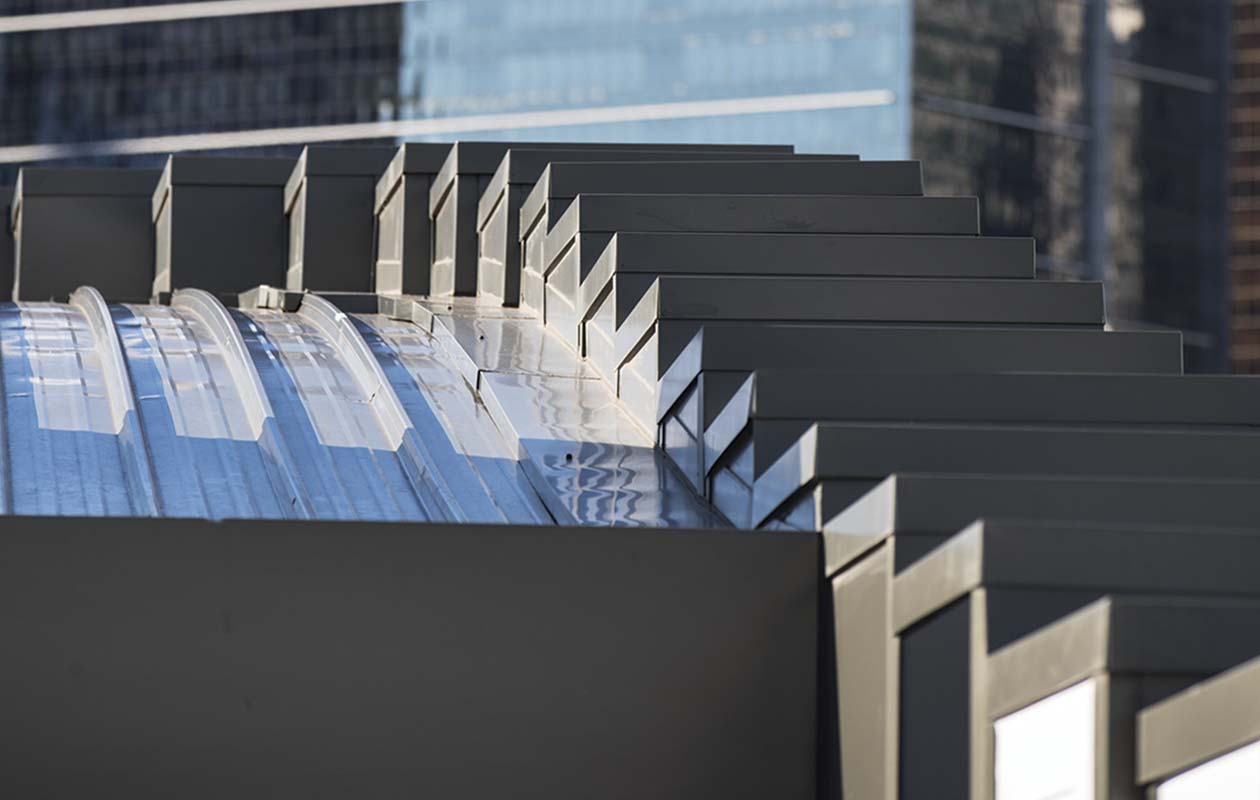

From the outset, product selection was key to providing that neat roof solution. The design required a building material that could meet the light-weight structural requirements of the project and its tight budget, while also meeting the aspirations the architects had for the architectural facade. Working to the mantra that controls can lead to beneficial outcomes, FJMT looked to Kingspan’s BENCHMARK Evolution insulated wall panels made from corrosion-resistant COLORBOND® Ultra steel in the colour Woodland Grey® to meet the very particular demands of their design thinking.

“What was great about the Kingspan product was the way it worked to a modular-type approach,” says Perry. “We were looking for something that we could clad the whole building in without having a whole series of horizontal joints. The Kingspan BENCHMARK Evolution panels’ structural properties allowed us to have incredibly long panels, up to six or seven metres long, which gave us basically one continuous long panel from ground level to the roof, and it also worked effectively as an interface with the glass.”

The architect, engineer and cladding contractor worked closely with Kingspan to resolve the design complexities of the rotating panels.

The regularity of the panel joins most obviously reference the ribbed hulls of ships, but it’s a steel motif that also recalls, at a more subliminal level, the patterning produced by water.

“Very early on we looked at some key things – one of them was water and how it ripples and sets a repetitive pattern. That gave us a clue about how we might profile the building, because you could have just done a sleek tube; you could imagine it all as vertical faces but that would have been really uninteresting and so we developed this idea of a repetition of elements and how that might develop into a building.”

The BENCHMARK Evolution wall panels made from COLORBOND® Ultra steel in the colour Woodland Grey® lent themselves well to the project and achieving the desired staggered- panel effect. FJMT had employed such vertical patterning for internal applications in the past, but this project was for it the first instance of its application as an external facade.

“The facade has to deal with and do a lot of things… it is the quiet innovation of the project”

James Perry Architect - Francis Jones Morehen Thorp (FJMT)

“With interior panelling you have a bit more freedom about doing what you want to do, but externally it was quite a challenge,” says Perry. “We worked really closely with the builder and Kingspan to work through all those complexities, particularly when you have panels rotating and what that means for waterproofing .”

The clients are delighted with the pavilion, an outcome the architects attribute to the dialogue and collaboration with the vessels’ naval custodians, who were actively engaged in the early design meetings and provided invaluable insight and advice. Perry finds much satisfaction in many aspects of the project but singles out the architectural facade for special mention.

“For me the north and south elevation are probably my favourite parts of the building because they do everything we hoped they would,” says Perry. “I love the way it has ended up working with the two vessels. The facade has to deal with and do a lot of things and, in this context, it is the quiet innovation of the project. If the facade had just one big panel it would have had such a different effect and impact than what has been achieved here with the panels rotating.”

How apt, then, that the main controls of the project – Vampire, Onslow, tide and current – continue to work with the Pavilion post-construction. Every day they have a different conversation with the facade, as moving water and vessels reflect on the panels, producing fine shifts and gradations in the appearance of the building. A beautiful reminder too that limitations can be seen in a positive light.

Panel Says

Built to mark the centenary of World War I and commemorate 100 years of Royal Australian Navy service, the Australian National Maritime Museum’s new Waterfront Pavilion occupies a narrow wharf between a navy destroyer and a submarine.

Taking its design cues from those vessels, and mindful of their propensity to move with the current and tide, the new building’s distinctive appearance results from rhythmically offsetting composite panels made from COLORBOND® Ultra steel in the colour Woodland Grey® to create a twisted carapace.

Like its ocean-going neighbours, the pavilion appears to float in mid-air, creating a striking new addition to this busy Darling Harbour precinct. Its organic and distorted form is an effective contrast to the more romantic shed nearby, which houses the main museum building.

Project information

Architect

Project

Australian National Maritime Museum Waterfront Pavilion, New South Wales

Awards

- 2016 Australian Institute of Architects NSW Chapter Awards – Commendation

Location

Australian National Maritime Museum - Darling Harbour. 2 Murray St, Sydney NSW 2000 View on Google Maps

Copyright © 2016 BlueScope Steel Limited ABN 16 000 011 058. All rights reserved.

No part of this publication may be copied, reproduced or distributed without consent. BlueScope Steel Limited, to the extent permissible at law, is not liable to any person for loss or damage arising from reliance upon information contained in this publication. The articles featured in this edition of STEEL PROFILE® are sourced, written, fact-checked and curated by the authors with editorial contribution from BlueScope Steel Limited. Any statements or opinions attributed to a person are the views of that person alone and do not necessarily reflect those of BlueScope Steel. The decision to use any particular product or material in the projects featured in this publication was made by the team involved in each project and not BlueScope Steel Limited. While care has been taken to verify the accuracy of details in this publication, BlueScope Steel Limited assumes no responsibility or liability for any errors or omissions in the content of this publication. All information is provided with no guarantee of completeness or accuracy.

Images shown throughout have been reproduced to represent actual product colours as accurately as possible. However, we recommend checking your chosen colour against an actual sample of the product before purchasing, as varying screens and devices may affect colour tones and finishes.

Every project is different and not all products are suitable for all applications, projects and environments. You should confirm the suitability of particular products for your project by contacting the supplier directly and by obtaining information and advice specific to your circumstances.

BlueScope generally recommends the use of COLORBOND® steel or ZINCALUME® steel for the majority of external cladding applications. BlueScope recommends routine preventative maintenance for eaves and other “unwashed areas” of structures that may not be regularly cleaned by rainfall. For information about product maintenance, including preventative maintenance, please call BlueScope on 1800 753 658. To determine whether a BlueScope warranty may be available for use of a product in your particular project, please visit bluescopesteel.com.au/warranties.

BlueScope, COLORBOND® and ® colour names are registered trademarks and ™ colour names are trademarks of BlueScope Steel Limited. Kingspan and Benchmark are registered trademarks of KINGSPAN HOLDINGS (IRL) LIMITED.

Submit your project

We encourage you to share your projects for consideration in a future issue of STEEL PROFILE® magazine. We invite you to submit projects that feature a ground-breaking or an innovative use of steel. We love celebrating and writing about such projects!