Sunkids Mermaid Waters

Sunkids Mermaid Waters on the Gold Coast evokes a sense of gathering, engendered by the encapsulating form of its striking roof, crafted from COLORBOND® Ultra steel in the colour Surfmist®.

Words: Riley Wilson.

Photography: Cieran Murphy.

Videography: The Local Production

Project Summary

On the Gold Coast, the circular form of Sunkids Mermaid Waters by RealSpace Creative – inspired by the embrace of a child – is the future-focused face of childcare.

The Gathering

On the Gold Coast, Sunkids Mermaid Waters is redefining what a childcare centre can be, with a striking roof form made from COLORBOND® Ultra steel that creates a distinct sense of embrace.

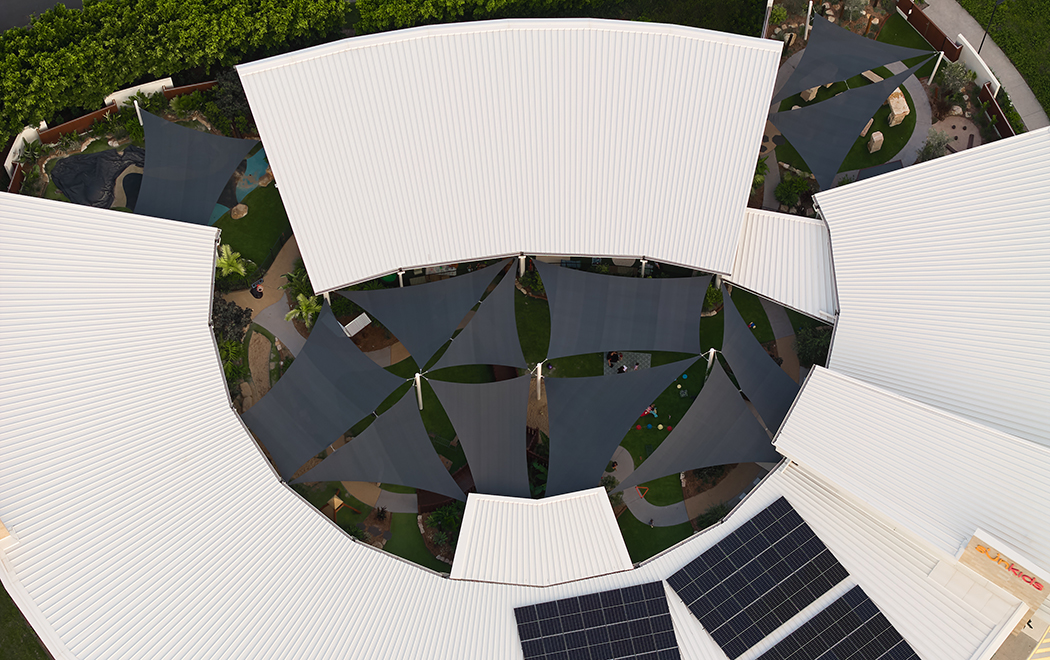

Beneath an impressively large circular roof – supported by hundreds of bespoke, light gauge steel roof trusses, made from TRUECORE® steel – a new generation of imagination-fuelled Queensland kids is embraced in a cocoon of creativity.

Light spills in through the floor-to-ceiling windows at Sunkids Mermaid Waters, a state-of-the-art childcare centre on the Gold Coast, illuminating each learning area, activity room and amenity space. A cavernous double-storey foyer invites parents and local residents to gather and connect, and a tricycle path – designed to spark curiosity and support the inquisitiveness of the young attendees – weaves through lush plantings in the protected, shaded internal courtyard.

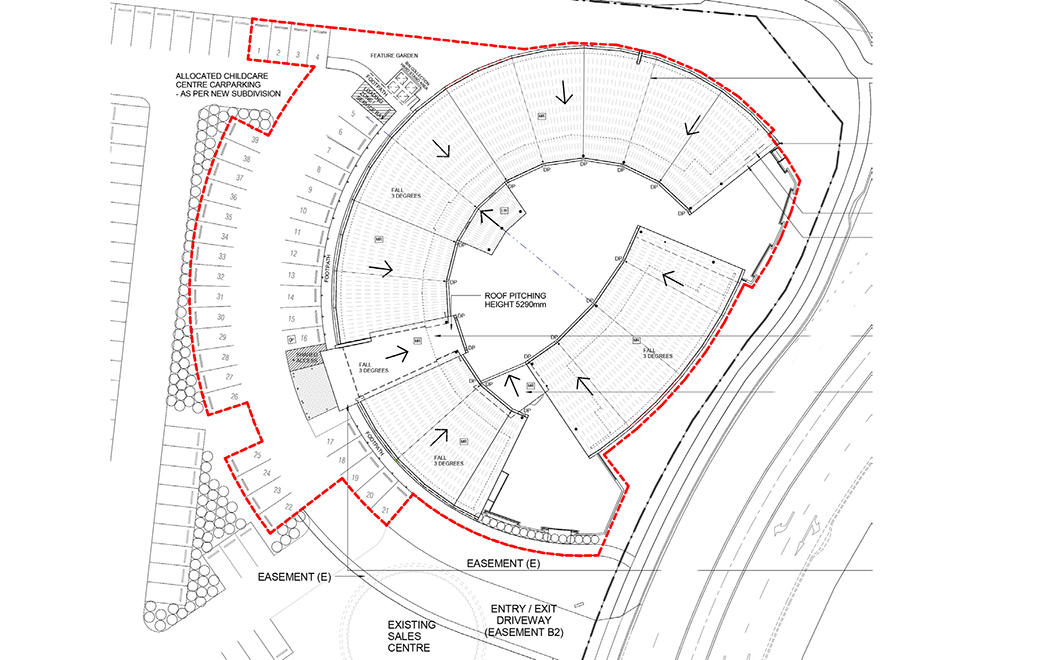

Viewed from above, the building appears as two sweeping curves that coalesce to encircle a central playscape that includes a miniature Stonehenge, timber play equipment, a vegetable garden and a roofed space – known as the piazza – designed for dining and group celebrations. Within the 1,183 square metres of internal space are nine age-specific activity rooms, radiating out from the community-centric lobby. Windows and doors are often left open to welcome coastal breezes and expose the children to the surrounding environment, gently heightening their awareness of the broader world.

“The warm embrace of a child is what inspired the shape of this building,” says architect Hooman Jaffar of RealSpace Creative. “For many children, the daycare centre is their first experience of life outside the home, so it was important that the building offered a nurturing environment – an extension of home – but was also a place of excitement, designed to both spark imaginations and challenge perceptions.”

While encapsulating the building’s core purpose of providing early education for 162 children, Jaffar designed the monolithic circular structure to echo its surroundings – a new residential precinct called The Lanes. The building’s circular form feels organic, softened by the absence of sharp corners and enriched with wide, open spaces.

“That’s why the building is strung along that curve, so every room has access to the playscape,” he says. “And it changes as you walk through the spaces and around the building. You never see a true corner; it’s always in motion, always fluid.”

At the project’s inception in 2016, a concrete form was originally considered; however, when the price was beyond the budget, the team switched to light gauge steel (LGS) framing for the structural elements of the build. Both the RealSpace team and Australian Framing Solutions (AFS) – the LGS framing consultant approached with the challenge of delivering the project on the tight budget – agreed that adjusting to a structure made from LGS frames which had been pre-fabricated off site would help to minimise on-site steel waste. With the frames being fabricated to exact specifications, as well as being light and easy to handle, the build program of the long-awaited project was also improved, without compromising the design intent.

“It changes as you walk through the spaces and around the building. You never see a true corner; it’s always in motion, always fluid.”

HOOMAN JAFFAR RealSpace Creative

AFS founder and CEO Jake Gundry estimated that switching to prefabricated LGS framing for the walling and roof trusses saved 90 days in the build program. “The originally conceived concrete bunker was transformed into a building made from lightweight framing crowned with a spectacular circular roof,” he says. The elimination of ‘wet trades’ – such as the concreters who would have been originally required – helped reduce the delivery timeline, while the fast installation of the roof frames also accelerated the pace of the internal fit-out.

Environmental challenges associated with the coastal location were carefully considered at every stage of the build, from initial planning through to completion in 2024. Lightweight and termite-proof, TRUECORE® steel was the ideal material choice for the temperate coastal location. AFS fabricated the steel framing, including 300 individually designed roof trusses of bespoke lengths and shapes – each spanning more than 14 metres. The trusses were delivered in clearly marked packages for easy assembly and installed on site by five tradesmen in just eight days using mobile cranes.

The corrosion resistance provided by TRUECORE® steel’s metallic coating with Activate® technology gave further peace of mind considering the property’s proximity to a marine environment. An essential consideration was the effective integration of large shade sails designed to cover the internal courtyard. These sails needed to withstand the typical wind pressures experienced in the region. In collaboration with the architectural and engineering teams, AFS designed and prefabricated custom steel connections that secured the shade sails to the building while minimising horizontal and vertical movement being transferred to the main structure.

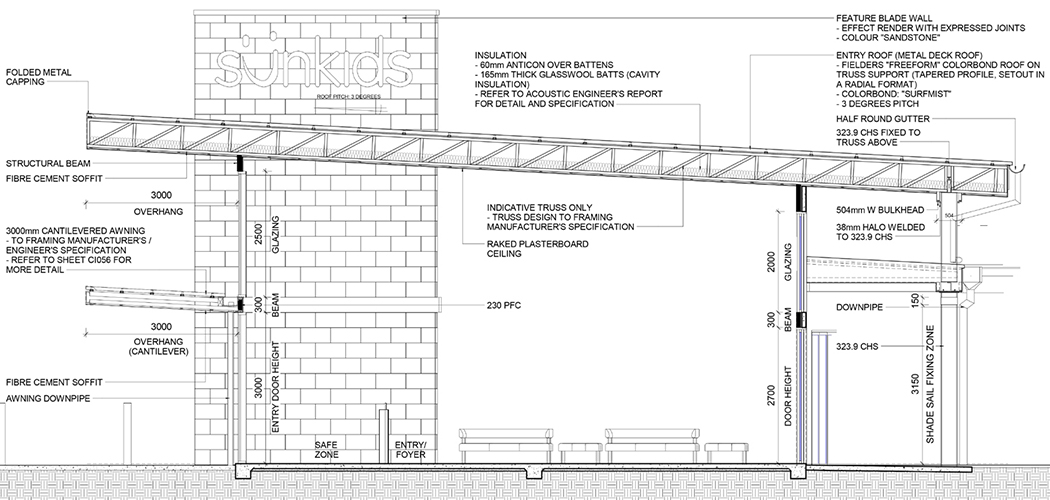

In this stunning but harsh environment, a durable roof that could withstand the conditions with minimal ongoing maintenance was required. COLORBOND® Ultra steel in the colour Surfmist® in Fielders FreeForm® profile was the ideal choice to create the roof, which covers 1,905 square metres.

The roof sheets were rolled into their shape on site and quickly adjusted and installed, providing an affordable and durable solution for the demands of the roof’s radial design. The inherent flexibility of the FreeForm® profile accommodated the complexity of the tapered roof, enabling smooth transitions between the planes and other building elements, such as the roof’s fascia, and ultimately delivering an uninterrupted roof form with high aesthetic appeal.

“The idea of breaking down the building into prefabricated components made things much easier with steel,” Jaffar says. “The thin nature of steel at its edges was really exciting for us. We always imagined this building with a streamlined roof profile, but fine detail at the roof’s extremities as it transitions effortlessly to the walls below was only possible with steel. Additionally, it was paramount for us to create something lasting and we wanted a building that would require only minimal maintenance. Washed with regular rainfall, a steel roof gives us that longevity and peace of mind.”

“We always imagined this building with a streamlined roof profile, but fine detail at the roof’s extremities as it transitions effortlessly to the walls below was only possible with steel.”HOOMAN JAFFAR RealSpace Creative

With regular sea breezes, it was only logical, Jaffar explains, to maximise natural ventilation throughout the structure. Each room opens onto the internal courtyard, with commercially rated, tinted glazed windows supporting constant airflow. Combined with a substantial roof cavity filled with high-performance insulation, the natural ventilation helps reduce heat gain and enhance comfort throughout the building.

The expansive roof provided an ideal platform for solar, with photovoltaic panels installed to generate energy during daylight hours. Internally, hard-wearing, honed-concrete and durable, high-performance vinyl flooring were selected for their longevity and, ultimately, lower environmental impact. “All of the material choices,” Jaffar says, “came together to create a thoughtfully designed building,” one that provides its young residents with an enduring space to begin their journey to understand their impact on the environment.

Originally conceived as part of a broader community masterplan, the childcare centre now serves as a focal point for the surrounding residential and commercial development, standing as a benchmark for innovation in architecture and sustainability – delivering on material integrity, aesthetic intent and civic purpose. “We are hoping Sunkids Mermaid Waters is a catalyst for some new thinking and some adjustments to the masterplan,” says the architect. “It is quickly becoming a community icon.”

STEEL DETAILS | A TECHNICAL DIVE INTO SUNKIDS MERMAID WATERS

With a nearly 2,000-square-metre footprint, the expansive roof of Sunkids Mermaid Waters was thoughtfully considered from concept through to completion. Positioned at the heart of a residential neighbourhood, the roof was designed not only to contribute meaningfully to the urban landscape for decades to come, but also to withstand the challenges of its coastal setting.

‘Cool roofs’ combine high solar reflectivity and high thermal emittance to reduce the amount of heat absorbed by the roof, helping to lower internal temperatures. For the centre’s roof, Jaffar and the team selected COLORBOND® Ultra steel in the colour Surfmist®, a gentle off-white shade with inbuilt Thermatech® solar reflectance technology that further reduces heat absorption. Surfmist® was also chosen for its high solar reflectance index of 81 as well as its visual harmony with the surrounding community. Additionally, COLORBOND® Ultra steel also offers enhanced corrosion resistance, ideal for the location.

For the roof profile, the team opted for Fielders FreeForm®, a concealed, clip-fixed profile with distinctive standing-seam-style ribs that deliver strong visual appeal, especially when viewed from the surrounding elevated buildings. The profile was selected not just for its aesthetics but also for its ability to taper, allowing for complex roof configurations to be achieved in line with an architect’s vision.

The use of the Fielders Mobile Mill allowed the project’s on-site team to make continuous micro-adjustments to the roof sheeting, aiding the efficient delivery of the complex circular footprint. “The speed and efficiency of steel construction were primary factors in its selection for the project,” Jaffar says. “Steel also allowed us to create a huge ceiling cavity that is capable of housing a substantial level of insulation,” thereby reducing the reliance on artificial cooling.

Large sections of the roof were optimised for solar panels, producing enough energy that air-conditioning is only used nominally. The sunshade and verandah space also help to defer heat transfer into the main structure. The internal courtyard and open spaces required a substantial sunshade to protect the children and reduce heat gain. When the original design was conceived in concrete, attaching shade sails to the main building was a relatively simple engineering concept.

However, when the design shifted to lightweight steel, the architecture and engineering teams had to develop a solution that transmits lateral forces without transferring wind loads into the main structure. “Collaborating with the engineer and the architect, we designed an attachment for the structure that allowed the shade sails to move both horizontally and vertically without transferring the load back to the building’s frame,” says Jake Gundry of Australian Framing Solutions.

BEHIND THE DESIGN: WATCH THE STORY OF SUNKIDS MERMAID WATERS

Project information

Architect

RealSpace Creative

Project

Sunkids Mermaid Waters

Awards

- 2024 Steel Excellence Awards, Queensland and Northern Territory Award for Innovative Cold Formed Steel Buildings

Location

1 Lakes Esplanade, Mermaid Waters QLD 4218 View on Google Maps

Copyright © 2025 BlueScope Steel Limited ABN 16 000 011 058. All rights reserved.

No part of this publication may be copied, reproduced or distributed without consent. BlueScope Steel Limited, to the extent permissible at law, is not liable to any person for loss or damage arising from reliance upon information contained in this publication. The articles featured in STEEL PROFILE® are sourced, written, fact checked and curated by The Local Project with editorial contribution from BlueScope Steel Limited. Any statements or opinions attributed to a person are the views of that person alone. The decision to use any particular product or material in the projects featured in this publication was made by the team involved in each project and not BlueScope Steel Limited. While care has been taken to verify the accuracy of details in this publication, BlueScope Steel Limited assumes no responsibility or liability for any errors or omissions in the content of this publication. All information is provided with no guarantee of completeness or accuracy.

Images shown throughout have been reproduced to represent actual product colours as accurately as possible. However, we recommend checking your chosen colour against an actual sample of the product before purchasing, as varying light conditions and limitations of the printing process may affect colour tones.

Every project is different and not all products are suitable for all applications, projects and environments. Some products may perform better than others in certain applications and conditions. BlueScope generally recommends the use of COLORBOND® steel or ZINCALUME® steel for the majority of external cladding applications.

BlueScope recommends routine preventative maintenance for eaves and other “unwashed areas” of structures which may not be regularly cleaned by rainfall. To determine the most suitable material for your project, please contact your supplier or see steelselect.com.au. For information about product maintenance, including preventative maintenance, please call BlueScope on 1800 064 384. To determine whether a warranty may be available for use of a product in your particular project, please visit warranties.bluescopesteel.com.au or call BlueScope on 1800 064 384.

COLORBOND®, TRUECORE®, FREEFORM® and ® colour names are registered trademarks of BlueScope Steel Limited.

If you have any questions, you can contact us at steeldirect@bluescopesteel.com.

Submit your project

We encourage you to share your projects for consideration in a future issue of STEEL PROFILE® magazine. We invite you to submit projects that feature a ground-breaking or an innovative use of steel. We love celebrating and writing about such projects!