Symmons Plains Homestead

A gracious Georgian homestead has been modernised and its outbuildings refurbished and connected to the main house with COLORBOND® steel, ZINC HI-TEN® steel and TRU-SPEC® steel creating a harmonious marriage of old and new structures.

Words: Editorial team led by Brydie Shephard.

Photography: Anjie Blair

Project Summary

A historic Georgian homestead in northern Tasmania has been modernised with a new insertion by Cumulus Studio, where steel creates a harmonious marriage of heritage and new structures.

A Modern Marriage

Drawn from the classical architectural vernaculars of Greece and Rome, Georgian buildings of the 18th century were all about proportion, with windows placed on grids and functional parts of homes relegated to the sides or in separate out-buildings. Ornament, while encouraged inside the home, was largely absent from a building’s facade, with a home’s size and surrounding gardens a preferred way to communicate grandiosity.

Nineteenth-century Tasmania, with a prosperous local economy driven by tin and ship building industries and a vibrant agriculture sector, attracted migrants bringing with them a predisposition towards Georgian-style villas. A number of these can be found in the Launceston region, including the Symmons Plains Homestead near the town of Perth.

The 808-hectare site had been a farming property since the early 1820s when Reverend John Arndell Youl was granted the property. In 1839, the homestead was built: a modestly scaled Georgian villa with typically Palladian landscaping.

The property was sold in 2011 to Clovelly Tasmania, a local farming syndicate managed by a worldwide corporation. The new owners recognised the need to restore and refurbish the homestead, wanting to preserve the stories and history imbued by Youl and the seven subsequent generations of his family who called Symmons Plains their home.

At the same time, they wanted to introduce modern amenities, while respecting the heritage of the homestead and its two out-buildings – a granary and stables which were in poor condition – which they envisioned as new accommodation for visiting business associates from interstate and overseas.

The clients commissioned Cumulus Studio, an award-winning architecture and interior design practice with offices in Launceston, Hobart, Melbourne and Adelaide.

With a collaborative, inter-studio ethos and a number of local, adaptive-reuse projects in their portfolio, Cumulus approached the project with experience and enthusiasm.

On their first site visit, the team – led by architect Todd Henderson – immersed themselves in the existing structure, looking under existing floorboards and climbing through the crumbling outbuildings to get a proper feel for the site. It was this hands-on approach that appealed to the clients, solidifying Cumulus’ commission.

"The new owners recognised the need to restore and refurbish the homestead, wanting to preserve the stories and history imbued by Youl and the seven generations of his family who called Symmons Plains their home.”

Important to the brief was to connect the two outbuildings to the rear wing of the main building, creating a coherent cluster of useable spaces for a family of seven, plus guests.

“The existing Georgian building was austere and relatively featureless,” says Todd. “It was quite solid with only small openings, like a huge block. So, the idea was to do the antithesis of that with a glazed link so that when you are in the interstitial spaces you get a very different feeling.”

Todd is happy to acknowledge the inspiration of the great Italian architect, Carlo Scarpa. Scarpa was famous for his interventions into existing, historical buildings and marrying the basic architecture with hand-crafted details. Like Scarpa’s best-known works, such as the Museo Castelvecchio in Verona and the garden of the Fondazione Querini Stampalia in Venice, Symmons Plains was a heritage project which aimed to restore the original building, but at the same time transform it into a functional, modern home. And, as with Scarpa, the idea was to form a true marriage of old and new where both had their separate identities, but worked harmoniously together.

It was a four-year project which began with necessary remedial work to the base building with specialist stonemasons, expatriates from Britain, repairing the foundations. The structural integrity of the building had to be restored (having been damaged by tree roots), damp-proof courses put in, brick walls re-built and some poor additions removed, along with the 1960s kitchen. “We had to peel back the things added over time,” says Todd, “and get it back to what it originally was.”

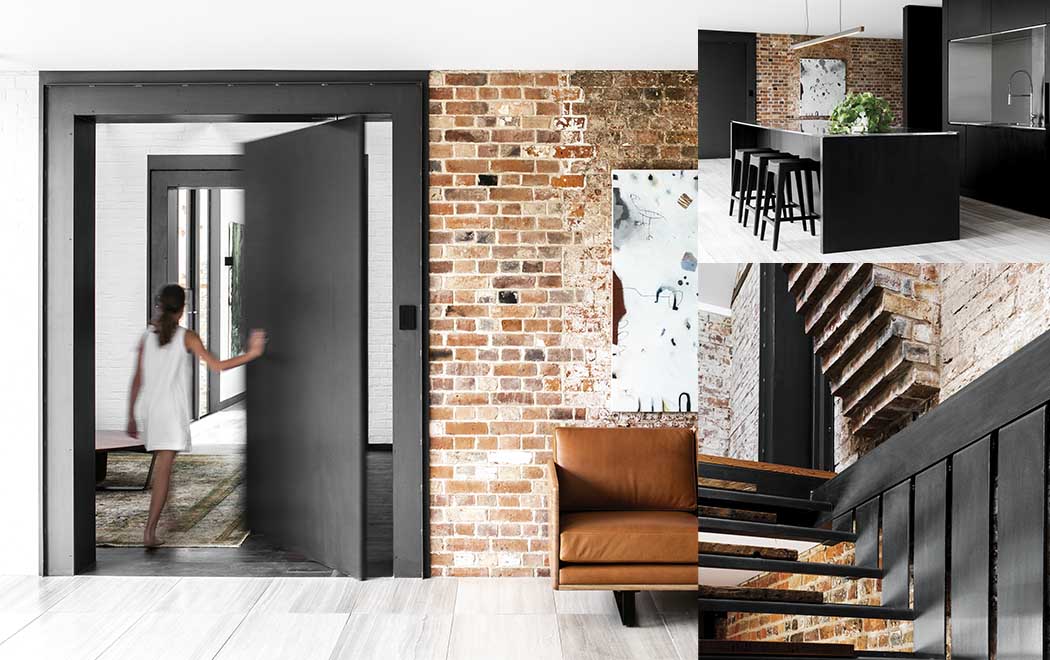

Inside, the history of the building is celebrated by the exposed brick walls and joists. But what really ignites the character and history of the building are the new interventions – the imaginative use of steel in two lightweight, glazed ‘tubes’ which appear as a singular connection that brings all the elements of the house together.

“All the existing building is brick and timber,” says Todd. “So, we wanted to do something quite different structurally and use a different aesthetic to what was there. The client was also very keen not to have any aluminium doors or windows. They wanted it to feel as though it was truly bespoke.”

The Cumulus strategy was that any new elements in the house had to have a connection to steel.

This formed an integral part of the architectural narrative: the coming together of old and new, where the “old” was identified by original materials with aged patinas, and the “new” defined with black steel architecture in dark colourways.

This is clear from the outside where the glazed ‘tube’ extrudes on either side of the main structure and where all of the windows and spacings are lined with slender steel mullions in Murobond® Bridge Paint in the colour Carbon, spaced at equal distances.

Fabricated by Crisp Bros. & Haywards from Rectangular Hollow Sections (RHS) of 75mm x 50mm x 3mm (manufactured by Orrcon Steel from BlueScope cold rolled steel coil), the mullions work alongside double-glazed glass to create a high-performance glazed solution with limited opportunities for thermal bridging. Importantly, the symmetrical spacing of the mullions forms a grid which replicates the orderly character of the original Georgian building.

From the facade, the transition between new and old is made explicit with the juxtaposition of steel and brick. This differentiation, set up as the home is first visible, is carried through to the interiors, with steel used again and again to identify any modern additions.

From staircases to shelving: the sleek, dark steel is set against the original materiality of the building as its antithesis, its visual contrast drawing attention to the home’s character as it becomes a tangible synonym for the “new".

Beyond building a visual narrative of the home’s refurbishment, steel was also used for its ability to provide a thin profile that could act as key structural features.

In the glazed tubes, the slender steel window mullions support the lightweight steel roof frame structure without the need for intrusive internal structural columns.

Accordingly, the living and dining area inside the tube is kept open and seamless, with uninterrupted views available through the entire tube. Hence, the steel mullions are both structural and aesthetic.

In addition to indicating new additions to the building, the choice of steel building materials also allowed for the existing structures to take precedence in the overall design narrative.

While the traditional Georgian building uses size to express grandeur, the new spaces employ walls of double-glazed glass and a low, flat roofing profile to be less conspicuous on the site.

Where the homestead features a hipped roof, the glazed tubes have a virtually imperceptible roofline, where a low pitch is finished with COLORBOND® steel in the LYSAGHT KLIP-LOK CLASSIC® 700 profile in the colour Monument®.

With good spanning-capacity and no need for exposed fasteners, the roofline is kept discreet, downplaying the new interventions and keeping the homestead's heritage buildings as the main features of the project.

Scarpa typically exposed the history of the building then juxtaposed it against carefully crafted contemporary interventions, or else he boldly contrasted one material against another, as in the steel staircase at the Museo Castelvecchio which floats against a wall of exposed brick.

Cumulus has adopted a similar strategy with the interiors at Symmons Plains. And once again an imaginative use of steel is the linking theme which creates a sense of unity throughout.

This ‘steel solution’ came about as a result of extensive collaboration, not to mention Todd’s own background. “My dad was a boilermaker and is now a steel estimator and I spent my younger years in the shed welding and using steel in an interesting way.”

This provided the backdrop to working with “a couple of the guys” at the steel fabricator, Crisp Bros. & Haywards in Launceston to see how it could all come together with the glass.

“We worked up one-to-one samples,” says Todd. “It was quite good to work with the people who would be putting it together.”

Interior thresholds, where new openings have been created, have a steel surround fabricated from RHS and Equal Angle (EA) – which signals that it is a new opening as opposed to an existing one. With the pivot doors, these surrounds act like reveals.

In the new kitchen space, located in the glazed addition, stainless steel has been used to tie interior and exterior together, with the material featuring on the benchtops and in the recessed bench space.

The showpieces, however, are the floating steel stairways in the home’s gallery and rumpus room (previously the granary and stables respectively). Fabricated by Crisp Bros. & Haywards from TRU-SPEC® steel flat plate, the two staircases are the most overt Scarpa references in the whole project.

In both cases, brickwork and timber are set off with bespoke steel detailing, where the flatness and smooth finish of the TRU-SPEC® steel contrasts against the aged textures of the original bricks.

The client had wanted floating stairs right from the beginning. The architects concurred and designed two stair structures, both hung from Parallel Flange Channels (PFC).

At the foot of the stairs in the gallery, bricks recycled from on-site demolition form an approach to the stairway, while the treads are timber salvaged from the previous, rotted, flooring.

Balustrading up the stairs and on the landing is crafted from RHS, EA and TRU-SPEC® steel flat plate. The ground floor now constitutes the social spaces of the house.

The client’s offices and formal lounge areas occupy the main building while the kitchen, dining and informal living spaces have been re-located to the new insertions where they can enjoy ample natural light and clear connections with newly extended outdoor social spaces, the terrace, pool and rear courtyards. These insertions, creating a link to the outbuildings, have allowed the stables and granary to be transformed into bedroom suites, garage space and an oversized rumpus room, completing the transition from austere Georgian homestead to refurbished family home.

“My dad was a boilermaker and is now a steel estimator and I spent my younger years in the shed welding and using steel in an interesting way.”

Todd Henderson Cumulus Studio

Project information

Architect

Cumulus Studio

Project

Symmons Plains Homestead, Tasmania

Awards

- 2020 Australian Institute of Architects Tasmanian Chapter, COLORBOND® Award for Steel Architecture - Commendation

Location

Perth, Tasmania View on Google Maps

Copyright © 2020 BlueScope Steel Limited ABN 16 000 011 058. All rights reserved.

No part of this publication may be copied, reproduced or distributed without consent. BlueScope Steel Limited, to the extent permissible at law, is not liable to any person for loss or damage arising from reliance upon information contained in this publication. The articles featured in this edition of STEEL PROFILE® are sourced, written, fact-checked and curated by the authors with editorial contribution from BlueScope Steel Limited. Any statements or opinions attributed to a person are the views of that person alone and do not necessarily reflect those of BlueScope Steel. The decision to use any particular product or material in the projects featured in this publication was made by the team involved in each project and not BlueScope Steel Limited. While care has been taken to verify the accuracy of details in this publication, BlueScope Steel Limited assumes no responsibility or liability for any errors or omissions in the content of this publication. All information is provided with no guarantee of completeness or accuracy.

Images shown throughout have been reproduced to represent actual product colours as accurately as possible. However, we recommend checking your chosen colour against an actual sample of the product before purchasing, as varying screens and devices may affect colour tones and finishes.

Every project is different and not all products are suitable for all applications, projects and environments. You should confirm the suitability of particular products for your project by contacting the supplier directly and by obtaining information and advice specific to your circumstances.

BlueScope generally recommends the use of COLORBOND® steel or ZINCALUME® steel for the majority of external cladding applications. BlueScope recommends routine preventative maintenance for eaves and other “unwashed areas” of structures that may not be regularly cleaned by rainfall. For information about product maintenance, including preventative maintenance, please call BlueScope on 1800 753 658. To determine whether a BlueScope warranty may be available for use of a product in your particular project, please visit bluescopesteel.com.au/warranties.

COLORBOND®, ZINCALUME®, LYSAGHT®, KLIP-LOK CLASSIC®, CUSTOM ORB®, TRU-SPEC®, ZINC HI-TEN® and ® colour names are registered trademarks and ™ colour names are trademarks of BlueScope Steel Limited.

Submit your project

We encourage you to share your projects for consideration in a future issue of STEEL PROFILE® magazine. We invite you to submit projects that feature a ground-breaking or an innovative use of steel. We love celebrating and writing about such projects!